Is it time to clean your Mark Andy print stations? If so, are you making efficient use of your maintenance and production schedule to avoid unnecessary downtime?

There are a variety of printing press types and each one requires different cleaning methods. The actual amount of cleaning time varies per business as the cleaning process depends on if it is being performed by one person or by a team of people. If you have multiple people working on the cleaning tasks, each person can remove a plate cylinder or an ink pan and individually clean the components. If you only have one person assigned to cleaning the press, it will take longer which also means you will experience more downtime and less print production time.

Types of Mark Andy Presses

Each type of Mark Andy press has different needs for cleaning and maintenance.

Of the listed types below which one are you using?

- Digital. Press options from Mark Andy include the Digital Pro which is an entry to mid-level digital label press designed to make digital printing a more accessible option to global converters. The Digital Series IQ is a digital hybrid label press and the Digital Series HD is a high-speed, production-class digital press perfect for any label application.

- Flexo. Flexo presses provide high production levels, application versatility and quick changeovers. Mark Andy’s flexo press line-up spans older generation drum presses, like the 800 Series to inline models. Their latest entries include the Evolution Series E5 and updated Versa Max, with performance options based on your production needs from simple to mid-web press and scalable full-servo flexo solutions.

- Offset. Presses offered by Mark Andy are presented in conjunction with Presstek. These printing presses are eco-responsible and made to streamline the print production process for high-quality printing results in a faster turnaround time.

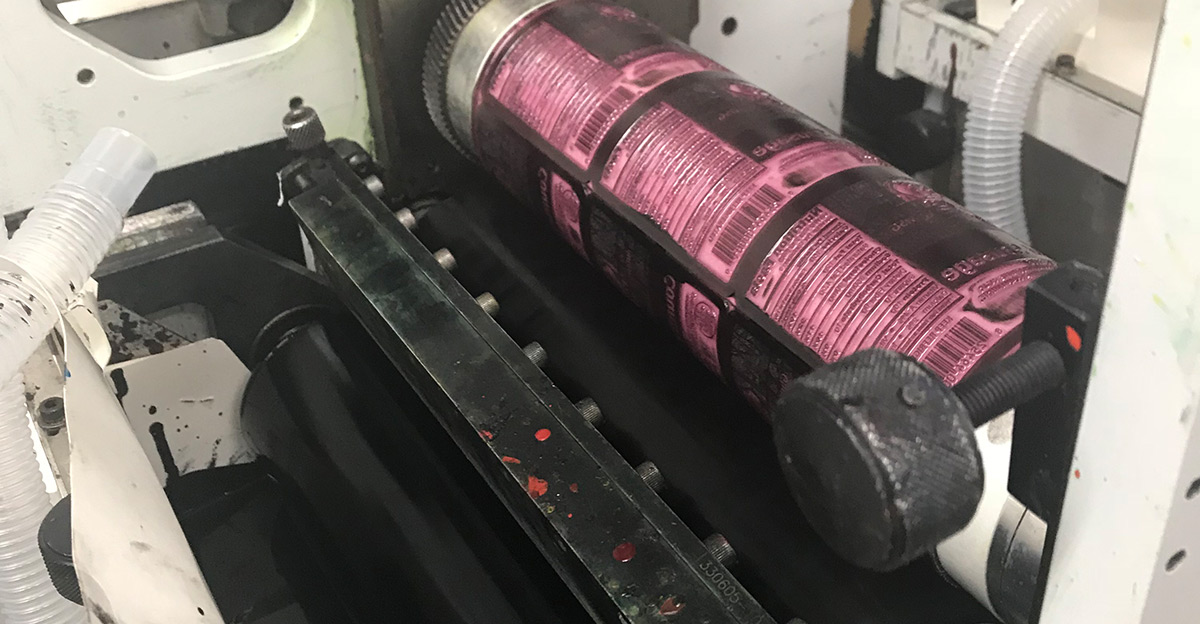

Make Cleaning Your Press Easier

Each Mark Andy press has different cleaning needs so it is important to know the cleaning time for each will vary. No matter which printing press you use for your business, all Mark Andy equipment options have the ability to be cleaned more efficiently using “Quick Change” drip trays and ink pan liners or fountains. These products are designed and manufactured to exacting standards to ensure proper fit and function. Drip trays, ink pan liners, and fountains are disposable, so they help to increase the productivity of both the press and the press team. This means “Quick-Change” products can be easily removed from the press, eliminating the need to wash OEM components by traditional means, either manually or by using expensive parts washers. This in turn eliminates water consumption, wastewater, electricity, and chemical reclamation requirements. Installing new disposable trays and liners completes the cleaning process and safeguards against ink contamination for the next press run.

Learn more about the ease of Mark Andy press cleaning when you contact us today.

Contact Us Now for More Information or to Request a Quote

Phone: 970-874-2852