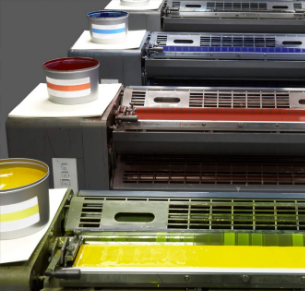

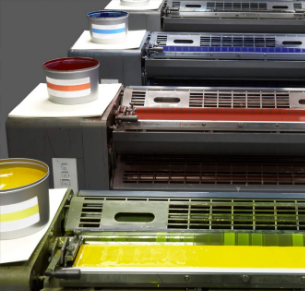

As North America’s only designer and manufacturer of disposable ink pan, fountain, and drip tray liners to the print industry, DIPCO has provided solutions to cut downtime and streamline your production operations for over three decades. Our high-quality product offerings eliminate your reliance on harsh chemical cleaning agents, expensive cleaning equipment, and excessive support personnel while practicing and encouraging environmental stewardship.

We partner with printing companies ranging in size from simple one-person operations to global corporations to develop innovative “Quick Change” solutions enabling press departments to become more efficient during press changeovers and print station cleanups.

We offer straightforward, easy-to-use products that facilitate increased productivity and reduce direct labor costs. Serving all major segments of the print industry, from flexo and offset to coating and laminating, DIPCO’s mission is to provide products and services to help businesses reach their full potential.

Our Company History

Our Commitments

At DIPCO, we consider ourselves partners in your success. In doing so, we commit to you our highest level of quality and customer service to ensure your business grows and thrives. We take pride in knowing our products help strengthen the foundation you’ve built to become a leader in your community and within the print industry.

We support and depend on the American worker utilizing:

- Paper harvested from US forests and manufactured in US mills

- Plastic pellets manufactured in the US

- Highly-trained team members for the hand-assembling of all DIPCO products at our manufacturing facility located on the Western Slope of Colorado

Our Environmental Impact

We empower people to streamline print operations by using products designed from recyclable materials. From repurposed USDA paperboard to in-house regrind efforts for all plastics, DIPCO is committed to limiting our carbon footprint in the printing industry. Please continue our efforts by starting your own recycling program.

DIPCO products

DIPCO products

- All paperboard waste is recycled & reused

- All paper drip trays are USDA bio-certified

- Plastic wipers are manufactured with 30% regrind material

- Unused regrind material is sold and used in the manufacturing of other US goods

- LED lighting is used in all production and office areas

- An average of 4.6M gallons of fresh water per year is saved by using ink pan liners

- Using Ink pan liners saves over 6 weeks of downtime per year

- All orders are made-to-order and ship within three working days

- 5-minutes is the average time spent cleaning an ink or coating station using DIPCO liners.

FUN FACT

240,000 lbs. of repurposed USDA paperboard per year are used to manufacture DIPCO products

Disposable Ink Pans & Drip Trays installed since 1984

Gallons of Water Saved by Using Ink Pan Liners