Troubleshooting Ink Viscosity Issues for Better Print Quality (Part 3 of 3)

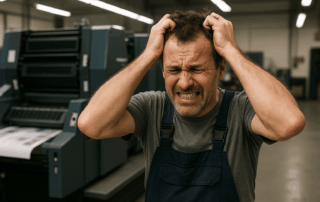

You’ve measured. You’ve logged. You’ve stirred. And somehow… your print’s still off. Welcome to the club. Viscosity doesn’t always shout at you—but it always leaves clues. And if you’re not catching them early, you’re just [...]

Measuring and Managing Ink Viscosity on Press (Part 2 of 3)

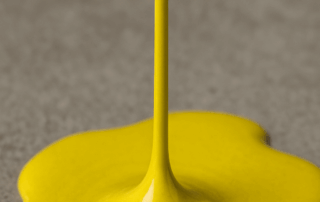

Let’s talk shop. Checking ink viscosity isn’t flashy—it doesn’t make anyone a printing rock star. But if you’ve ever dealt with streaky print, ghosting, or ink that starts drying in your ink pan liner before [...]

Ink Viscosity and Why It Matters (Part 1 of 3)

Ink viscosity sounds fancy, but it’s really about thickness—like comparing honey to water. You’d think it’s simple. Yet ask any press operator and they’ll tell you it can make or break a press run. You [...]

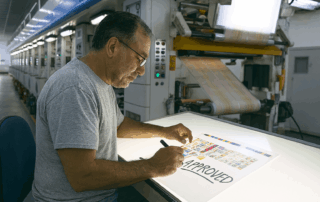

Proofs: Why They’re Essential—and What to Watch Out For

In flexographic printing, a proof is more than a simple preview of the product you’ll be printing—it’s your first line of defense against costly errors, miscommunication, and quality issues. A proof allows the press operator, [...]

Boost Lamination Efficiency with DIPCO’s Disposable Pan Liners for Comexi SL2 and ML2 Machines

In high-speed lamination environments, downtime for cleanup can cost valuable production hours. That’s why DIPCO is excited to introduce disposable pan liners engineered specifically for Comexi SL2 and ML2 laminators - a smarter, cleaner, and [...]

Best Practices for Using Ink Pan Liners in Flexo Operations

Flexographic printing companies across the industry are turning to disposable “quick change” ink pan liners to streamline operations, reduce cleanup time, and eliminate unnecessary mess. At DIPCO, we’ve engineered our liners for peak efficiency—but like [...]